How the YESS Standards Align with the Uyghur Forced Labor Prevention Act

By Sarah Jaques and Patricia Jurewicz

Responsible Sourcing Network’s (RSN’s) due diligence initiative YESS: Yarn Ethically & Sustainably Sourced aligns with several requirements of the Uyghur Forced Labor Prevention Act (UFLPA), with a focus on the middle of the supply chain. Signed into law on December 23, 2021, the UFLPA prohibits the importation of goods made with forced labor from the Xinjiang Uyghur Autonomous Region (Xinjiang), China. Due to the overwhelming evidence of state-imposed forced labor, the UFLPA creates a rebuttable presumption that all articles produced in whole or in part by manufacturers located in Xinjiang, or by entities that source either materials or labor from Xinjiang, are automatically barred from entry into the United States.

YESS is designed to drive forced labor out of cotton production globally by building due diligence capacity and managing an assessment of yarn spinners and fabric mills, key suppliers in the middle of the textile supply chain. The foundational documents, YESS Standard for Spinning Mills and YESS Standard for Fabric Mills (YESS Standards), require mid-tier suppliers implement and continuously strengthen effective due diligence management systems for risks of forced labor in cotton production in their supply chains.

Below is an analysis of how the requirements and approach of the YESS Standards align with Section VI. Guidance to Importers, part A. (p. 40 - 48) of the Strategy to Prevent the Importation of Goods Mined, Produced, or Manufactured with Forced Labor in the People’s Republic of China, issued by the Forced Labor Enforcement Task Force (FLETF). This strategy document was issued in June 2022 to provide guidance to importers on the implementation of and adherence to the UFLPA. Although the guidance applies to importers (commonly brands and retailers) and the YESS Standards apply to yarn spinners and fabric mills, companies importing cotton textile goods into the U.S. need to demonstrate their due diligence systems cascade throughout their entire supply chains all the way to the raw materials. YESS facilitates implementation of due diligence in the middle tiers of the supply chain.

Part A. Due diligence, effective supply chain tracing, and supply chain management measures to ensure that importers do not import any goods mined, produced, or manufactured wholly or in part with forced labor from the People’s Republic of China, especially from Xinjiang

Due Diligence

Engage stakeholders and partners

To be conformant with the YESS Standards, a spinning or fabric mill must collaborate with or support capacity building directly, through farm-level schemes, recycled cotton schemes, multi-stakeholder initiatives, public-private partnerships, or industry efforts, where they exist. Where such efforts do not exist, a mill needs to share knowledge and work toward a common approach to engage suppliers as well as other industry members and civil society stakeholders in an effort to mitigate risk and scale up effective measures.

Assess risks and impacts

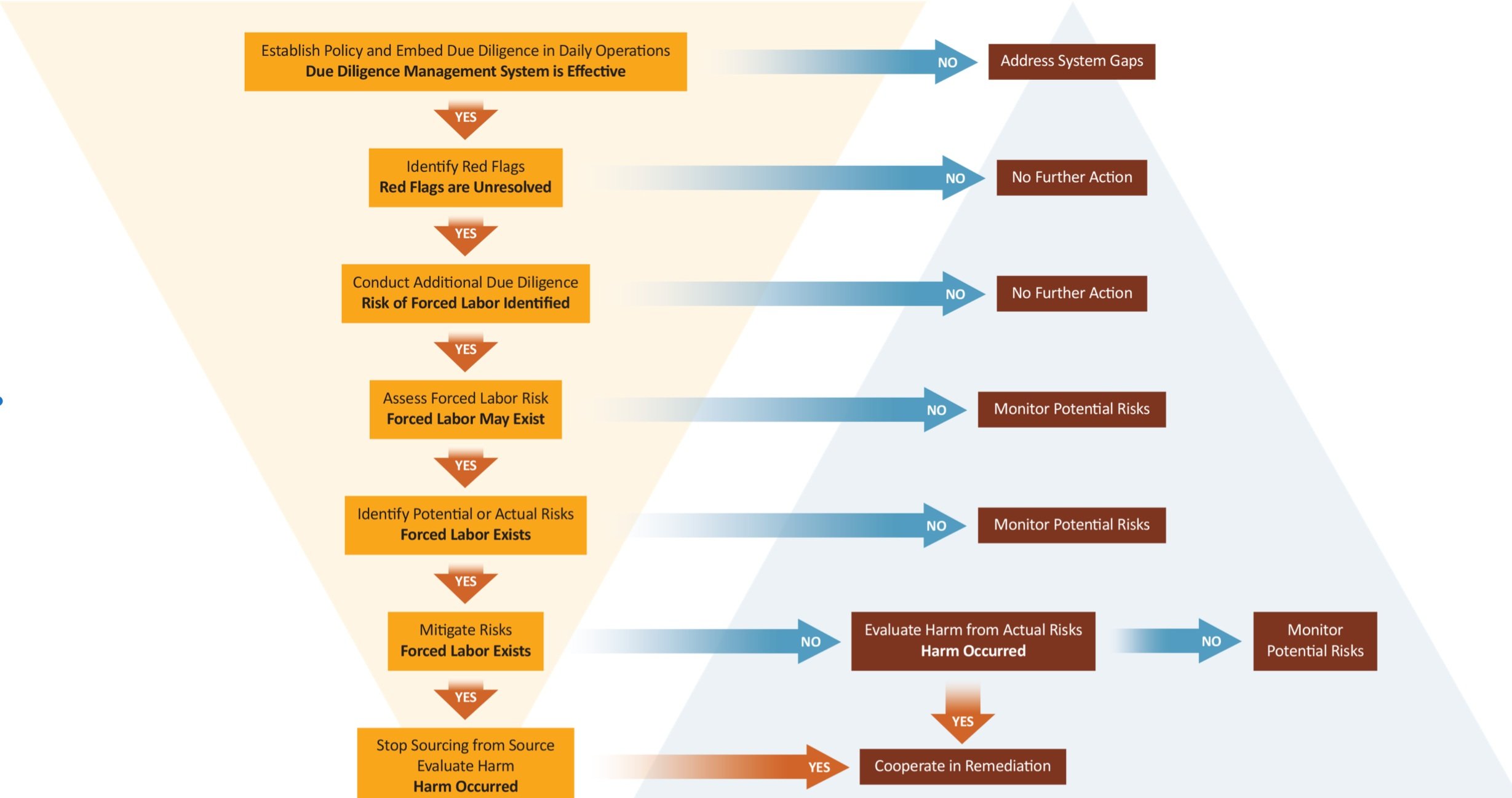

The YESS Standards require a mill to identify where there is a risk of cotton produced by forced labor entering its supply chain. To do this, a mill needs to implement a Know Your Supplier (KYS) process, which includes mapping and identifying the type, location, legality, and business relationship of all of its suppliers. It must also identify and assess all types of cotton inputs (unprocessed or recycled), their sources, and their transit risks. Where high risks are identified, a mill’s supplier is expected to implement enhanced due diligence of its own supply chain. A mill must prioritize risks based on established and justified processes and criteria. Once this is done, a mill needs to devise and adopt a risk mitigation plan as part of an effective risk management system. This graphic demonstrates the YESS Due Diligence Decision Tree for forced labor in cotton production. In a case where assessment, prevention, or mitigation is unfeasible, is unacceptable, or fails after it is attempted, the mill must disengage with that supplier in a manner that minimizes unintended negative impacts.

Develop a code of conduct

For mills, the YESS Standards play a similar role to an importer’s code of conduct in regards to minimizing forced labor in cotton supply chains because they provide a standardized framework for spinning and fabric mills to identify and address risk. The YESS Standards are based on the OECD’s Due Diligence Guidance for Responsible Supply Chains in the Garment and Footwear Sector. To be YESS-conformant, a mill is required to establish and implement a due diligence process to identify high-risk origins for all cotton inputs within its supply chain, to remedy harm if it occurred, and be assessed on that process annually by an independent auditor. The process needs to include information on cotton identification and determination procedures, cotton production data, gathered and evaluated information during KYS implementation, and engagement with local stakeholders to implement a risk mitigation plan.

Communicate and train across supply chain

YESS Standards require that a mill provides sufficient training to relevant employees covering critical information of their due diligence system and maintain training records. YESS requires all essential employees to have an adequate understanding of forced labor in cotton production and to be able to evaluate on the ground assessments and efforts. A mill needs to ensure that responsible staff have adequate time and resources to conduct their related due diligence responsibilities. As part of its risk mitigation plan, a mill must support and build capacities of suppliers, both direct and indirect, and to continuously improve due diligence of its cotton inputs and suppliers.

Monitor compliance

The YESS approach requires an annual assessment by an approved auditor of a spinning or fabric mill’s conformance with the corresponding YESS Standard. As a follow up to the assessment, a mill will have a six month improvement (corrective) action period to address any non-conformances. During the assessment, the auditor will conduct an extensive review of internal and external documents on a sample of shipments to triangulate information, and observe the worksite and associated facilities. To be conformant, a mill must meet minimum requirements for management systems, policies, procedures, inventory management, transaction tracking, risk mitigation planning and implementation, reporting, and remediation. A list of all cotton input transactions for the year must be shared with the auditor and reconciled with all existing inventories and outputs. Because labor conditions inside the mills are not in scope for the YESS Standards, YESS encourages mills to participate with other in-factory labor efforts to meet UFLPA in-factory labor compliance requirements.

Remediate violations

YESS standards require a mill to provide or cooperate in remediation when it has caused or contributed to a harmful impact associated with forced labor during cotton production. When possible, the mill should collaborate with other linked or contributing parties, and engage with the stakeholders who suffered harm related to forced labor. The remedy should be proportionate to the severity of the impact and meet national and international guidelines. To be conformant, it is expected that a mill starts to provide for or cooperate in remediation as warranted by Year 3.

Independent review

To be conformant, a mill must undergo an annual assessment by a YESS-approved third-party auditor. To be approved, an auditor must attend YESS online and in-person due diligence trainings, meet minimum scores in training quizzes, and be shadowed by a lead auditor. Although the design of YESS is to outsource the management of auditors and assessments to a global auditor management company, to ensure the quality and credibility of YESS-approved auditors and YESS assessments, there will be oversight by RSN/YESS of the auditor and audit firm approval process, and a review of the findings of the assessments by an Assessment Review Committee.

Report performance and engagement

To be conformant with the YESS Standards, a mill must disclose in a public report: its sourcing policy, how due diligence is incorporated into decision-making processes, procedures for assessing and prioritizing significant identified risks of forced labor in cotton production in its supply chain, its risk mitigation plan, stakeholder engagement, and access to remedy.

Effective Supply Chain Tracing

To be conformant, a mill must demonstrate it knows all of its suppliers (as mentioned above in #2 with the KYS process), has conducted basic due diligence on all of its suppliers before initial purchase of cotton inputs, and routinely reviews the business relationship with all of its direct suppliers.

For chain of custody implementation, YESS Standards require a mill to inspect all cotton inputs it receives into its warehouse and their associated documentation upon receipt. Each individual transaction of cotton inputs received needs to be inspected, weighed, identified and documented. Auditors are expected to obtain three different forms of evidence to validate conformance of each management system requirement under the YESS Standards. Evidence can be in the form of written procedures, observations of processes, interviews, meeting notes, training presentations, sign-in sheets, inspection checklists, and photographs. In addition to tracking documentation for all cotton inputs it receives, a mill needs to have a process to confirm the cotton inputs match their documentation and were not manipulated. Traceability technology tools could be used to support or enhance a mill’s management systems and procedures.

A mill must also ensure a supplier that provides cotton yarn is not mixing high-risk cotton lint into that yarn. If a mill produces cotton yarn or fabric that contains virgin cotton inputs and recycled cotton fiber, the corresponding YESS requirements for the virgin and recycled cotton inputs must be met. Since to be YESS conformant a mill needs to implement a forced labor risk assessment approach for all of its cotton input transactions, to disengage from suppliers that will not cooperate or where forced labor risks cannot be mitigated, and to demonstrate how it tracks all inputs through its manufacturing processes, the mill can blend a variety of cotton inputs together into a final product.

Supply Chain Management Measures

The underlying goal of YESS is to prevent and mitigate forced labor. A mill is expected to continuously assess risks in its supply chain, and implement enhanced due diligence when risks are found. To give guidance to mills so they have an understanding of the countries where there might be forced labor risk in cotton production, YESS has provided a Sample Procedure to Identify High-risk Origin for Cotton Lint. This sample procedure references U.S. and international reports that cite evidence of forced labor in cotton production, and should be updated when new report versions are released. To be conformant with the YESS Standards, a mill needs to establish its own procedure, demonstrate it is implementing its procedure, determine where risk may or may not exist, and implement enhanced due diligence when risks are identified.

As laid out in the YESS Conformance Continuum (p. 4, Table 2 in the Introduction to the YESS Standards), after all of the management systems are established in Year 1, starting in Year 2 a conforming mill needs to demonstrate with its risk mitigation plan how it is working with local stakeholders to prevent and mitigate potential or actual forced labor in cotton production where it has been identified and is linked to the mill’s supply chain.

At this time, RSN is not doing any capacity building or YESS assessments of spinning mills or fabric mills located in Xinjiang, since credible independent due diligence assessments and risk mitigation is not allowed and is not possible, and all cotton grown there is considered unmitigable.

Conclusion

Due to the various management system requirements, when products are sold to (direct or via finished goods manufacturers) and documents are shared with importers by YESS-conformant spinning and fabric mills, there is increased confidence the products will not contain unmitigable high-risk cotton, and that their corresponding documents are accurate and are the correct ones affiliated with a particular order/product.

An importer’s own upstream due diligence system as required by the UFLPA will be stronger by supporting YESS, by contributing to the development and roll-out of due diligence capacity building in the mid-tiers of supply chains, and by encouraging cotton yarn spinning and fabric mills to be trained and assessed on the YESS Standards.

If your company or organization is interested in getting involved with YESS, please contact info@sourcingnetwork.org